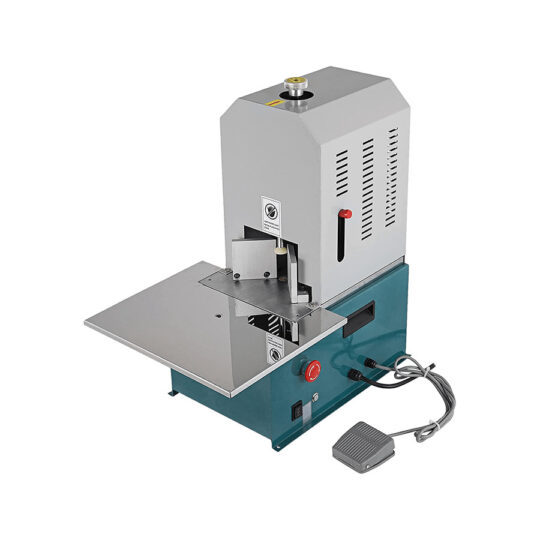

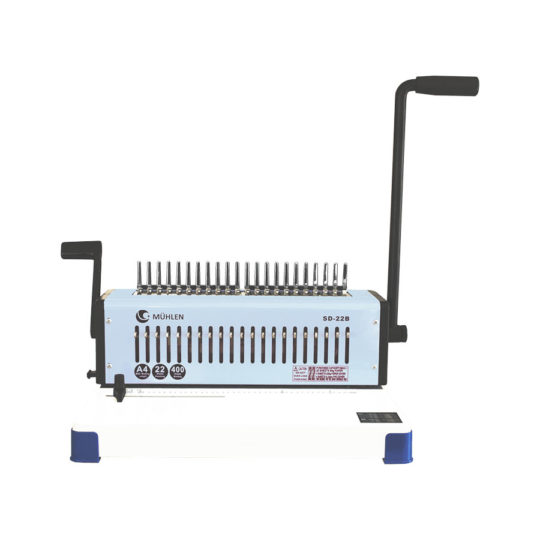

Free Hole Pin System |34 Pieces

The 34 free pin system of the model, which is extremely user-friendly, allows the user to punch documents in any range. For example, he can eliminate the half holes in the corners of the papers, and if he wants to attach a hanger to the binding, he can remove the pins of the middle part of the documents…

Punching 20 Sheets at a Time

It pierces 20 pages of documents comfortably and smoothly at a time, with much less pressure, with its punch blades made of special alloy steel with a 5-year warranty and accordingly, two-sided single pressure arm.

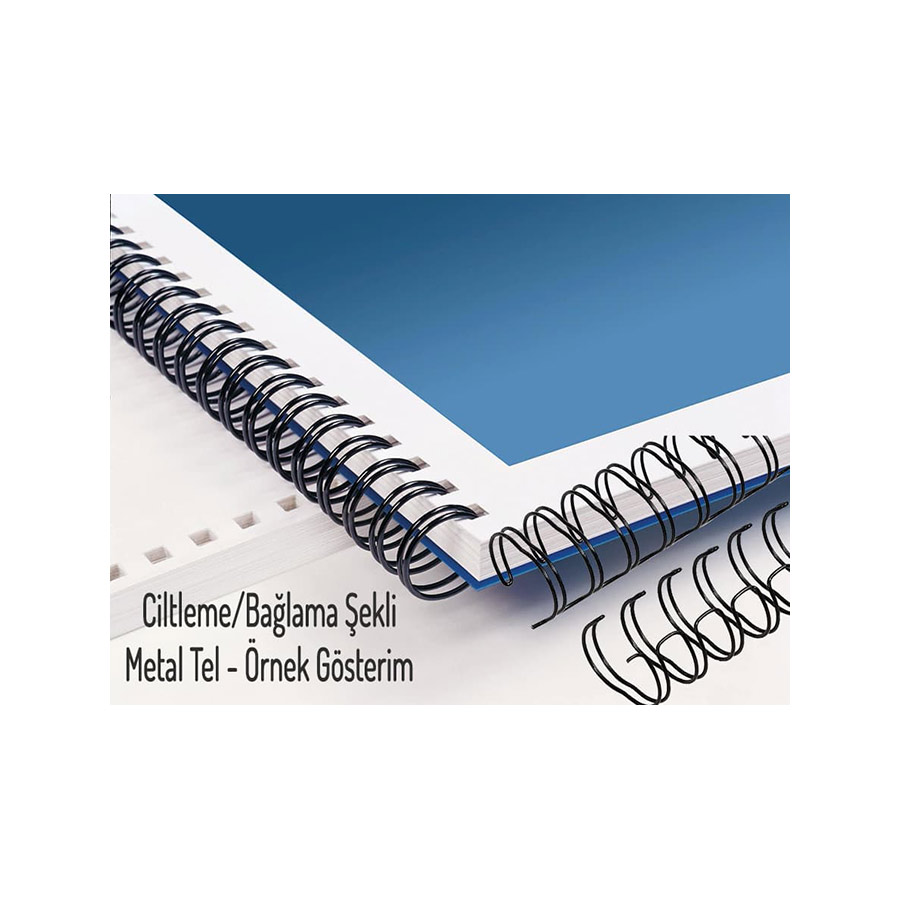

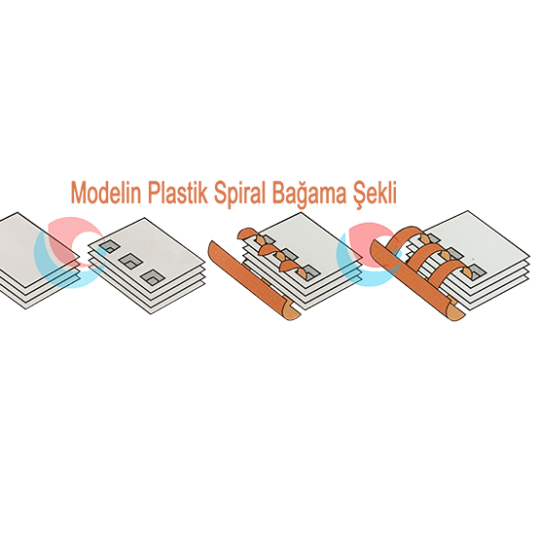

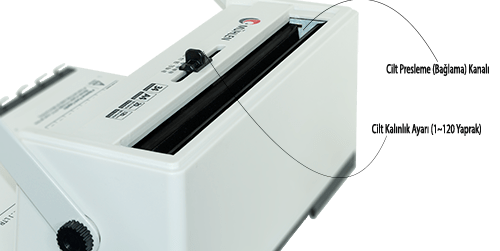

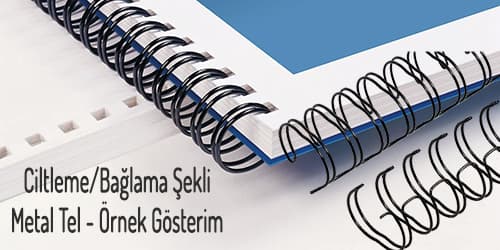

120 Page Binding Capacity

The model performs extremely easy and professional binding operations thanks to the burners to be bound between 1~120 sheets, the hooks that place the wire material, and the binding channel integrated into the machine, as well as the binding thickness adjustment that allows to adjust the number of pages to be bound.

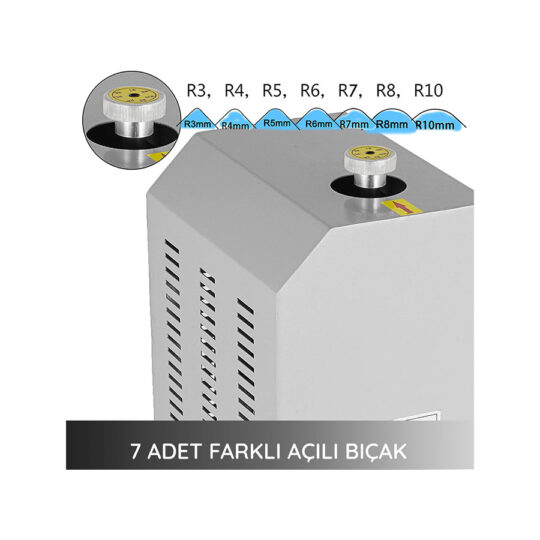

Adjustable Margin Setting

Thanks to the 3-level margin adjustment, the user can decide how much inside or how close to the corner to punch the documents and can make very stylish bindings. However, in general, thicker bindings can be punched closer to the corner, while thinner bindings can be punched from the inside.