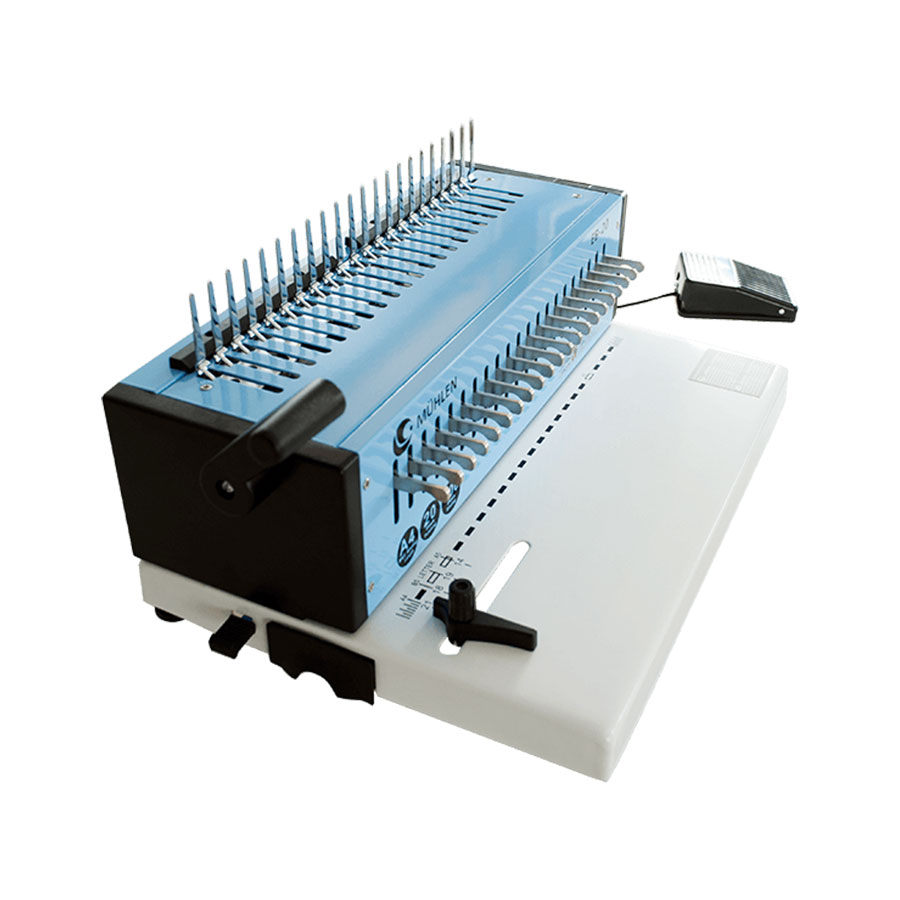

Electrical System

The Mühlen EB-20 binding machine, which works with a fully electric system, drills documents placed in the hopper in a fast and stable 21 pieces and 3×8 mm dimensions with the help of the foot pedal or the green button on the side of the machine.

Thanks to the electric motor, the user does not show strength to pierce the documents.

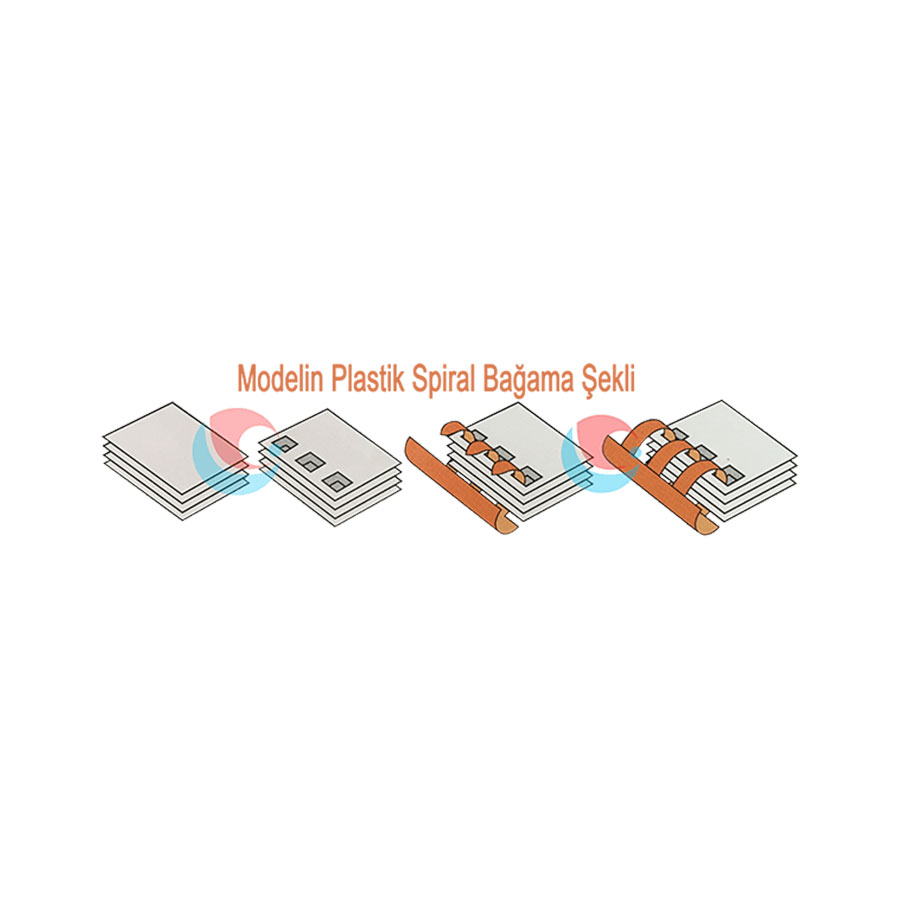

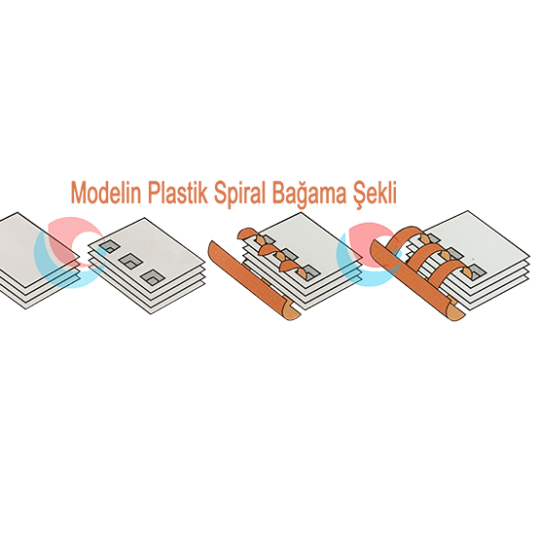

Binding up to 400 Sheets

Our model, which performs automatic binding and binding operations between 10 ~ 400 sheets at one time easily and quickly, connects each other at the end of the process by keeping the previously punched leaves easily with its specially developed binding arm.

Thanks to its extra maintenance and non-spoiling parts, it always works with the high performance of the first day.

Free Pin System

The most important feature of the EB-20 is that it has a pin free pin ”system.In MÜHLEN EB-20 model, it allows the user to not drill the corners of the documents and adjust the distance of 21 holes according to his wish.

In this way, the unpleasant appearance of the half holes in the corners and edges is prevented and a more elegant and uniform binding is performed.

Margin Adjustment and Waste Bin

With improved margin adjustment, the model features a 3-stage margin system for how much internal or external document holes are set.

The user can perforate the documents at any rate by leaving 3.5 and 7 mm margins. However, the paper waste generated during the punching process is stored in the waste bin, allowing it to be easily discharged.