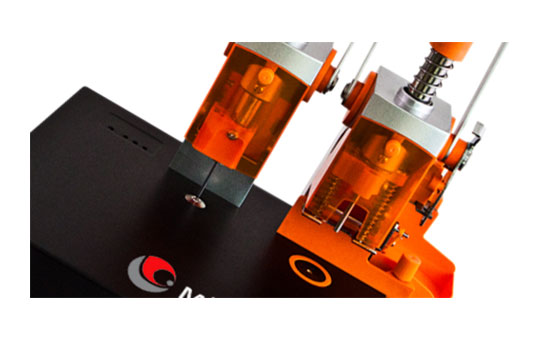

Fast Riveting

The Mühlen CD-400 model, which works with electricity, performs the thermal document riveting in a short time such as 15 seconds.

In addition, the body and interior parts made of steel are manufactured to serve for many years thanks to the construction. Heat and impact resistant steel riveting nail is guaranteed for 5 years and is ideal for use all day long.

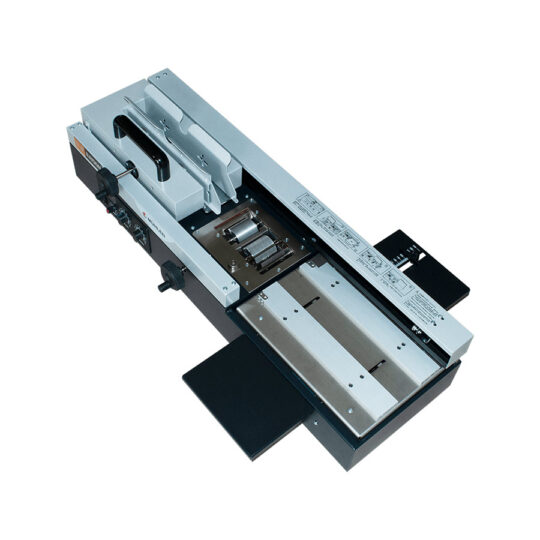

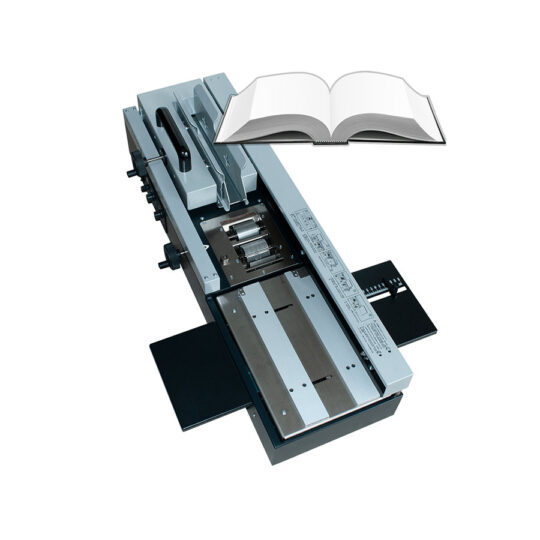

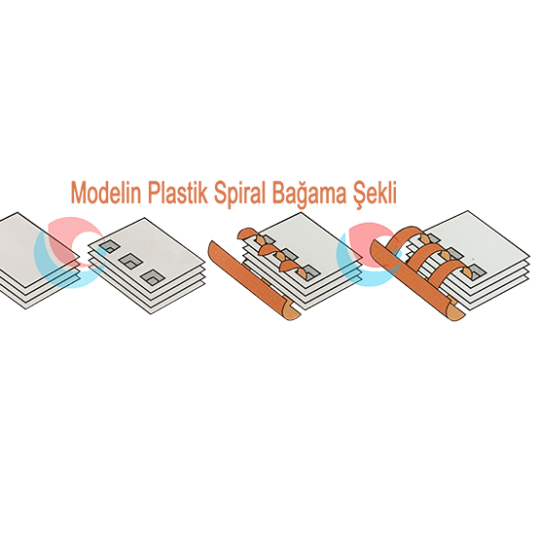

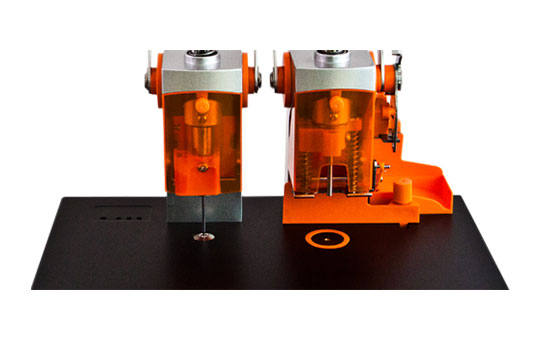

Automatic Riveting and Binding

The model with automatic rivet hole drilling and automatic rivet tube adjustment and cutting system is extremely easy to use.

In move 1, you open the rivet hole on the document, and in move 2, the plastic tube snaps into the rivet hole. After this process, and lastly, by heating both ends of the plastic tube inserted into the document, it provides expansion and tightening.

Improved Warning and Warning Systems

Thanks to its warning and warning system, it has the ability to warn the user with light and sound when it is ready for operation.

In addition, the Mühlen CD 400 binding machine automatically shuts down after completion of the process and warns the user in an audible and illuminated manner.

Setting Margins

The model, which allows the adjustment of the front and the margins, leaves the riveting process within the millimeter escaping from the corners completely at the user’s preference.

In this way, catalog and other document binding operations are performed in desired size and quality. In addition, it will automatically switch off after 25 minutes when not in use with the energy saving system.